food grade

Magnetic separator equipment

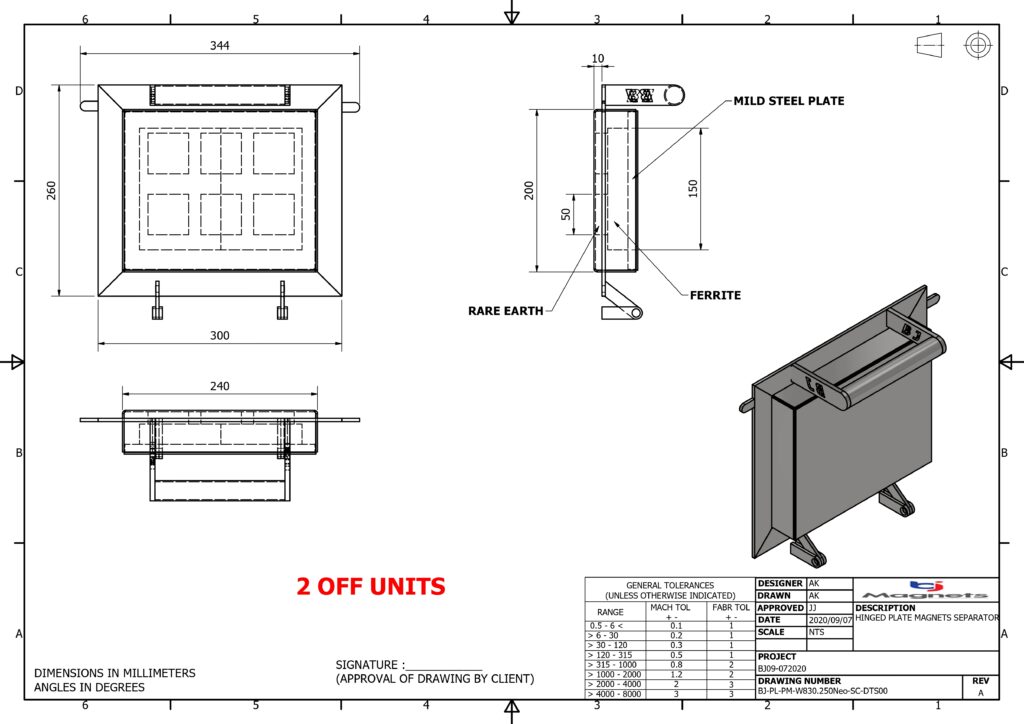

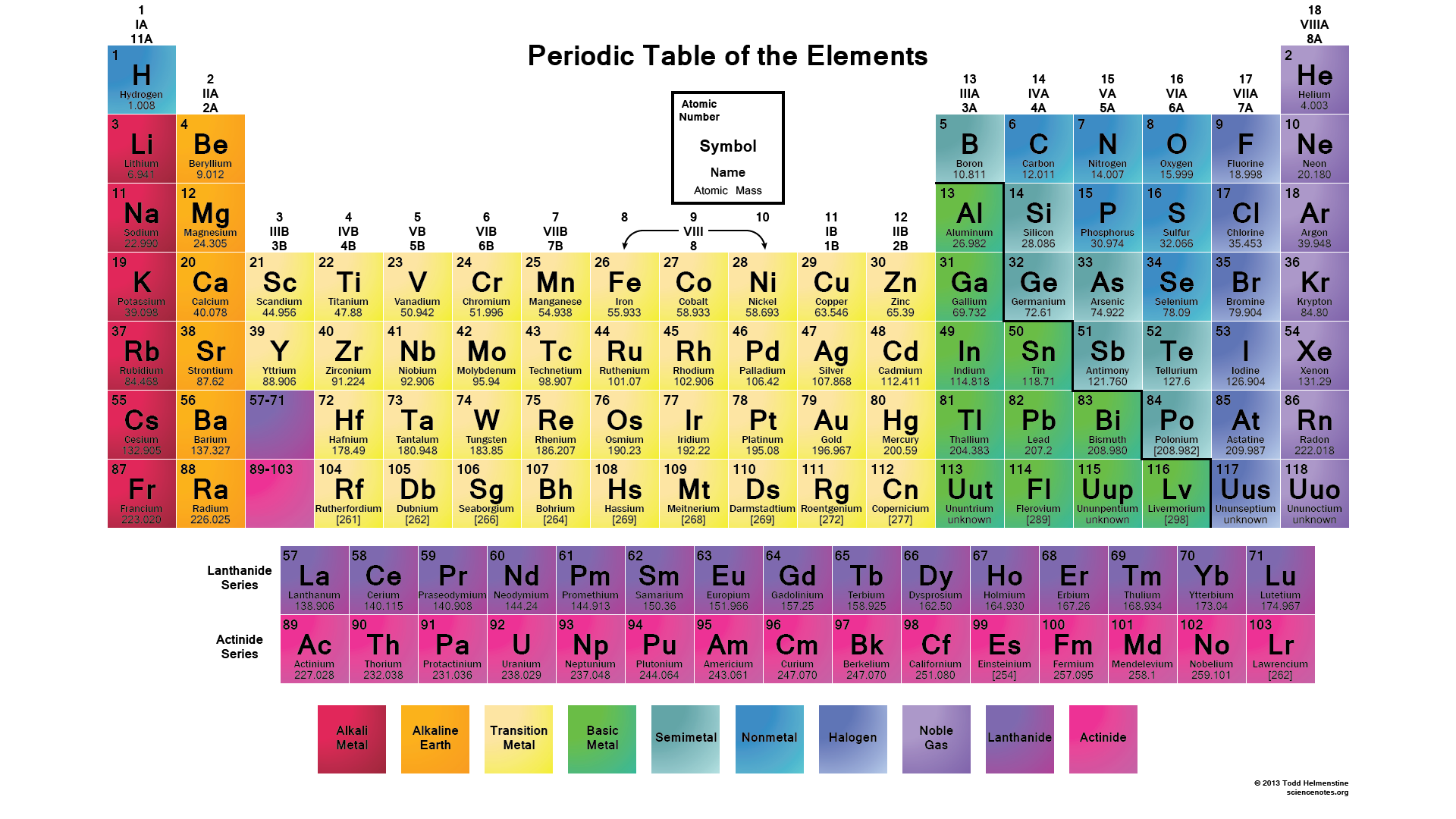

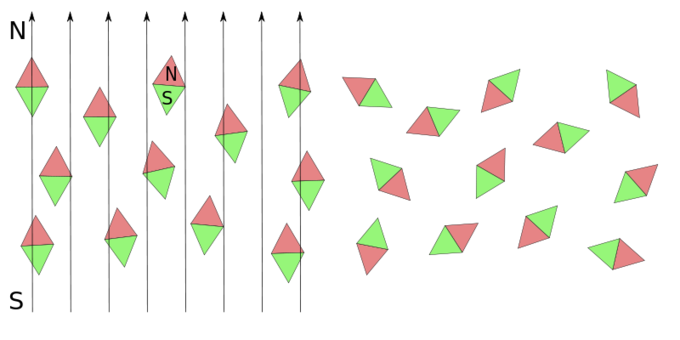

BJ Magnets is a South African well-established Mechanical Engineering Company speciliazed in manufacture of bespoke Engineered Permanent and Electro-Magnet Separator or Recovery Equipment (used in mining), as well as their relevant Assemblies. We are specialized in Design, Manufacture and Supply of Magnetic Separator or Recovery Equipment; hence immersed in minimizing the risk of metal contamination in Food, Beverage, Dairy, Pharmaceuticals, Plastic products etc. We also have expertise in supply of magnetic equipment and heavy duty equipment for mining minerals such as (but not not limited to) manganese, ore, copper, chrome, silver, aluminium, coal, cobalt, diamond etc… And as a result of our sophisticated engineered technology, our customers have quality produced products on the market, with all serenity possible.

BJ Magnets is ISO 9001:2015 certified company by SABS for Quality Management System. All our Magnetic Separator Equipment are designed, manufactured and supplied under observation of the principles of the HACCP International Food Safety Standard 0909MAGSEP 1-2010. Moreso, to the bargain of their effectiveness, the internal and external aspect of the magnetic equipment is produced according to the food health and safety standard in terms of the building materials; which is austenitic stainless steel of grade 304 or 316. Thereof upon completion, a certificate of Factory Acceptance Test (FAT) which is valid for 12 months is issued; in which case the equipment shall not be subjected to the anual validation.